Portfolio

Our Portfolio

Our clients value the highest quality and safety for their critical systems and have exacting standards that are measured in parts per billion, Microns, Megohms, Immediate danger to life and health, Safety integrity levels, particles per cubic ft, millikelvin, 99.9999%, 10 to the minus 9 to name a few. They are leaders in their fields, Australia’s leading research universities and tech start-ups creating Australian grown technology for a cleaner, greener and smarter world.

Silanna Semiconductor

Pinkenba Brisbane Queensland

Clean room build and process services

Completed March 2022 - $28.5M

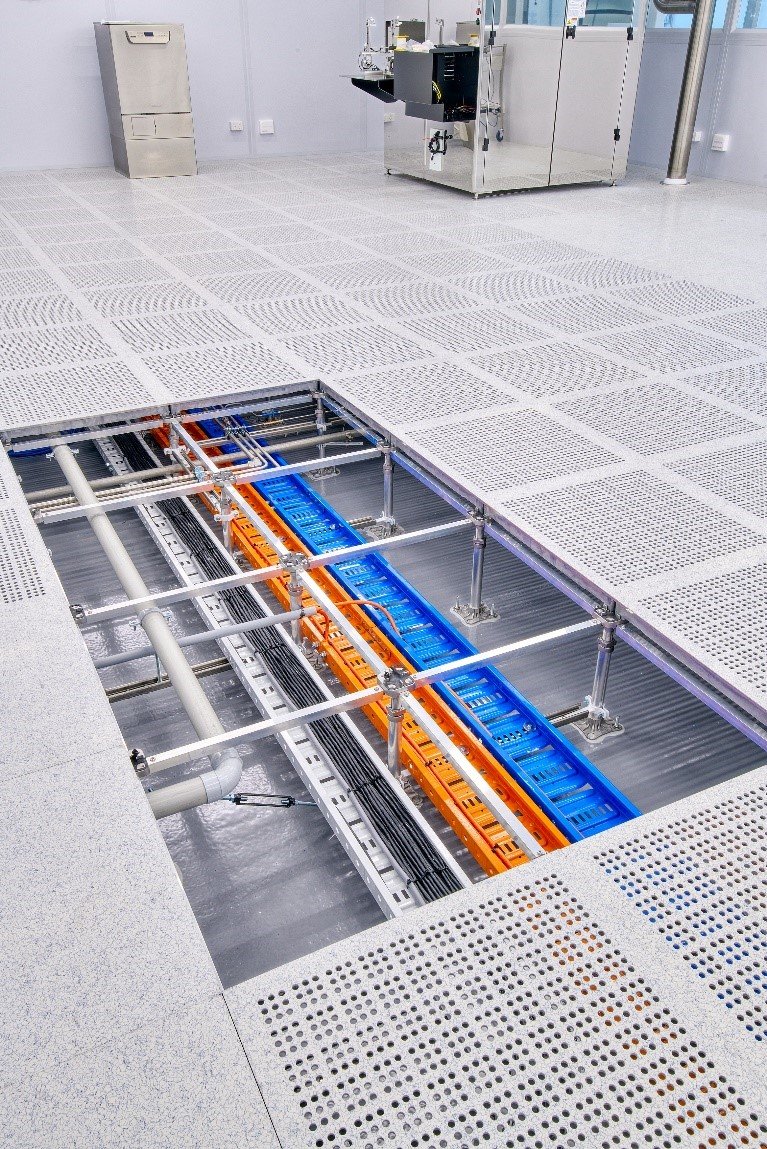

Project Management, Design and Construction of a Semiconductor manufacturing facility for the manufacture of ultra-low wavelength UV LEDs. This is a state-of-the-art Semiconductor ISO 5 cleanroom including a wide range of utilities including, Umech was engaged from the concept design stage through to the final commission of the facility.

• Specialty Gases

• Ultra High Purity Gas manifold panels

• House Gas distribution for Nitrogen and Compressed Air

• Ultra-Pure Water (18MegaOhm) plant and ring main system in PVDF

• Process Cooling Water - 6” SF4 stainless steel ring main system

• 120,000 Litre Liquid Nitrogen Storage and distribution ring main with phase separators

• 3.5-Megawatt electrical upgrade including 2 750kw diesel generators and a 500kW UPS

• HVAC and construction for 830m2 Cleanroom.

• 230m2 Class 100 Cleanroom

• 600m2 Class 10000 Cleanroom

• Cleanroom fit out works and laboratory fit out

• Semiconductor Tool installation

• Life Safety system for Oxygen depletion gas detection

• Detailed sample submittals for critical components with traceability and material inspection reports

FDC

Sydney University

Engineering Technology Precinct

Levels 7, 8, 9 lab gas and life safety design and installation

Completed March 2023

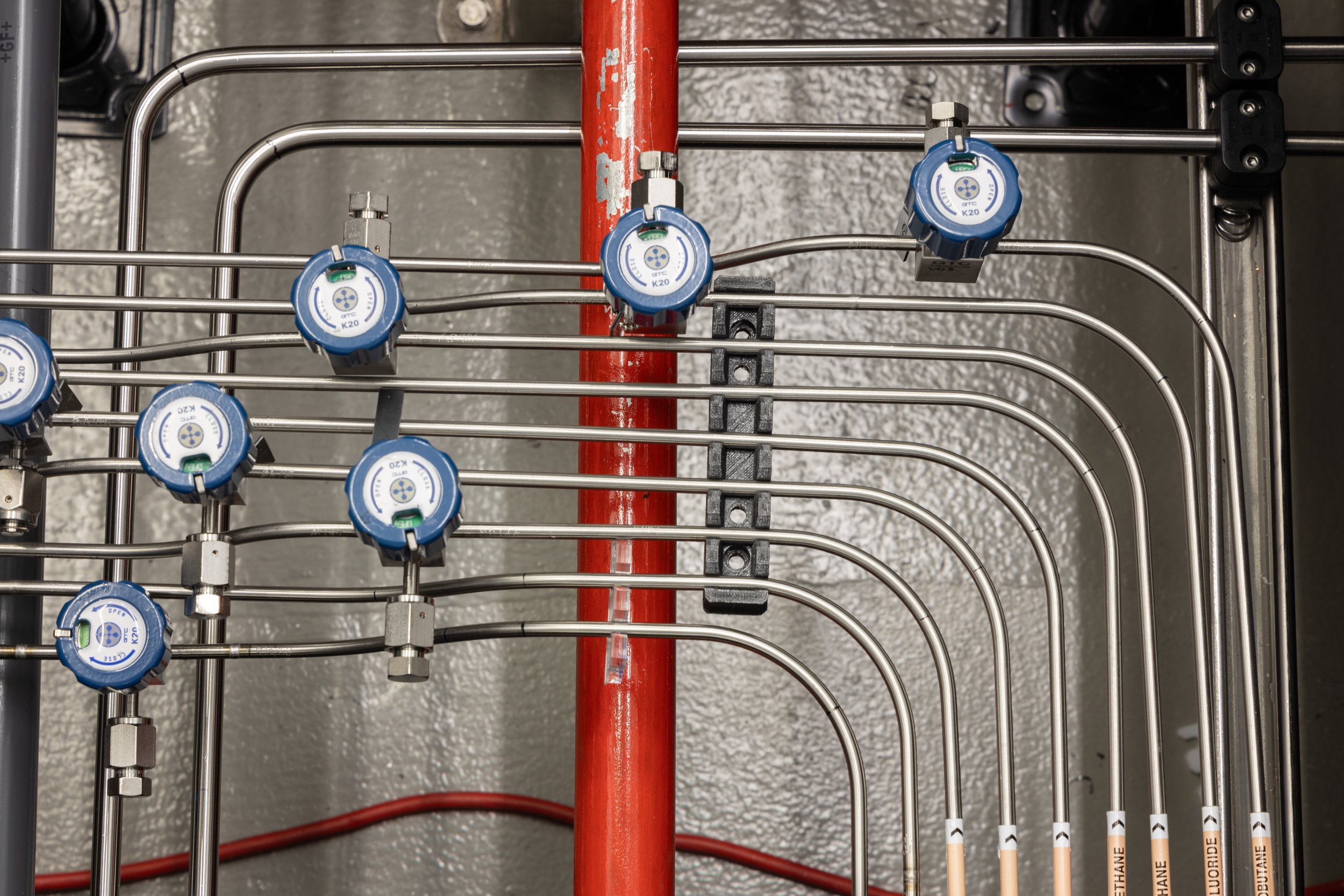

Design and installation of lab gas and life safety systems for three levels of labs in building J03. Lab gases included house gases (Compressed air, Nitrogen, Argon and Vacuum), inert specialty gases (Carbon Dioxide, Oxygen, Helium etc) and ultra-high purity toxic and hazardous gases (Hydrogen, Methane, Carbon Monoxide, Hydrogen Sulphide and Ammonia).

Piping routing drawings, coordination of design with other service disciplines in Revit

hydraulic sizing calculations on all of the gas lines

User design meeting coordination

Design of the Life Safety System to comply with AS61508. It included gas hygiene assessments of all spaces, user meetings to complete LOPA assessments to determine required SIL values for safety instrumented functions SIL Verification calculations and device proof test procedures

Design of Life Safety system operation including production of control system architecture drawings and cause and effect matrices

Umech procured all required plant including 11 gas cabinets, numerous gas manifolds and Life Safety sensors

Over 10 km of piping was installed including copper and ultra-high purity electropolished stainless steel tubing which was orbitally welded

Fabrication of three PLC based control cabinets for the Life Safety System. Factory and Site Acceptance Testing for control system

Pressure testing of all gas pipe lines. Helium Vacuum leak testing of all orbitally welded gas lines

Operating and maintenance manual, as built drawings and asset register to University of Sydney requirements

National measurement Institute - Australian government department of industry science and resources

Farindon constructions

Gas measurement Facility

Lindfield December 2024

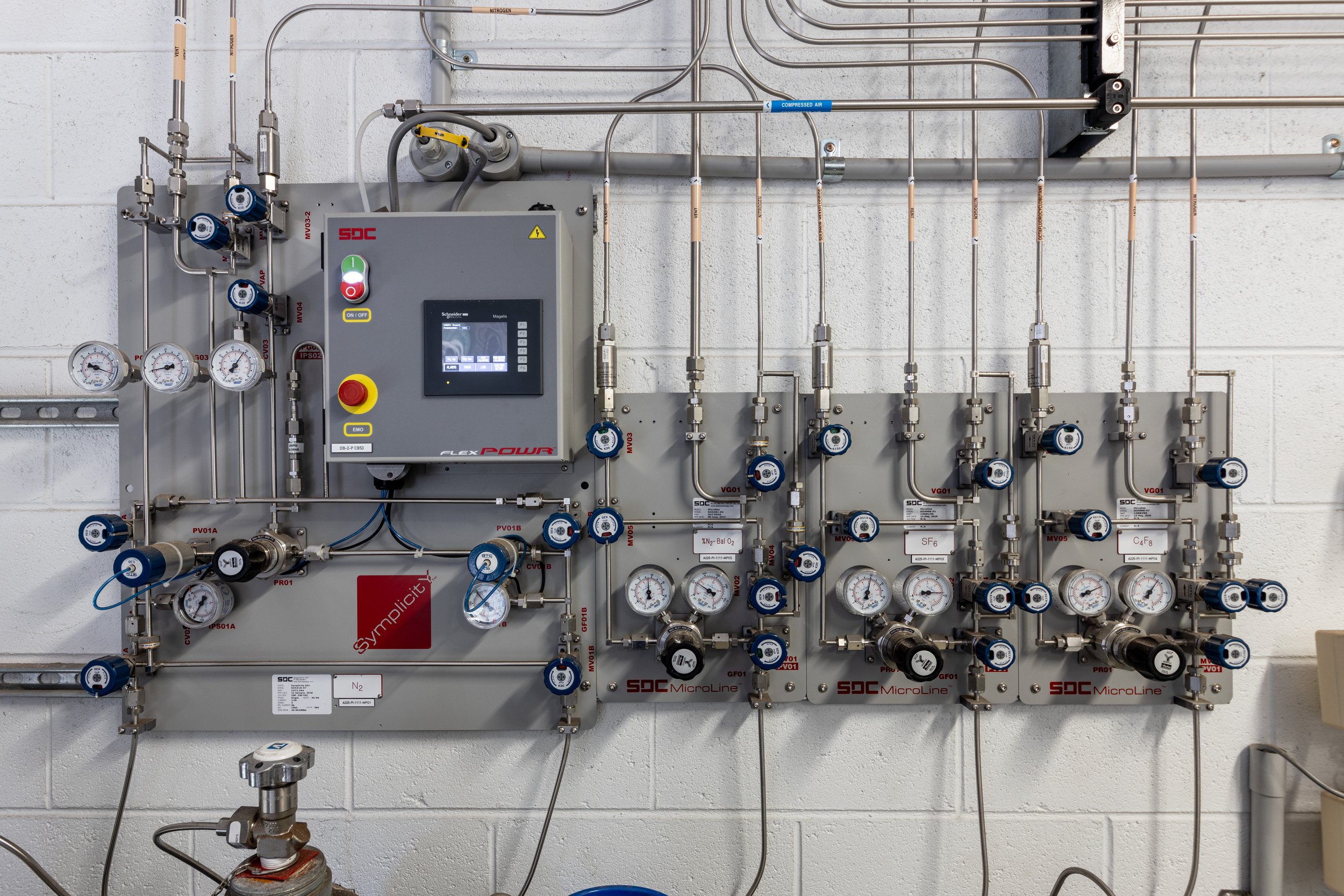

Umech is proud to announce the successful completion of a collaborative laboratory project in partnership with Farindon Constructions Pty Ltd. This project showcases Umech's expertise in delivering demanding designs. Supply and installation of UHP process gases, Vacuum Systems, Gas Cabinets, Custom fabricated Valve Manifolds- and Auto changeover panels for UHP (6N) Gases and gas detection Life Safety System.

Umech provides years of design and coordination expertise to reach the Standards required of our national measurement institute.

University of Sydney

Sydney Nanoscience Hub building

2018 - Ongoing

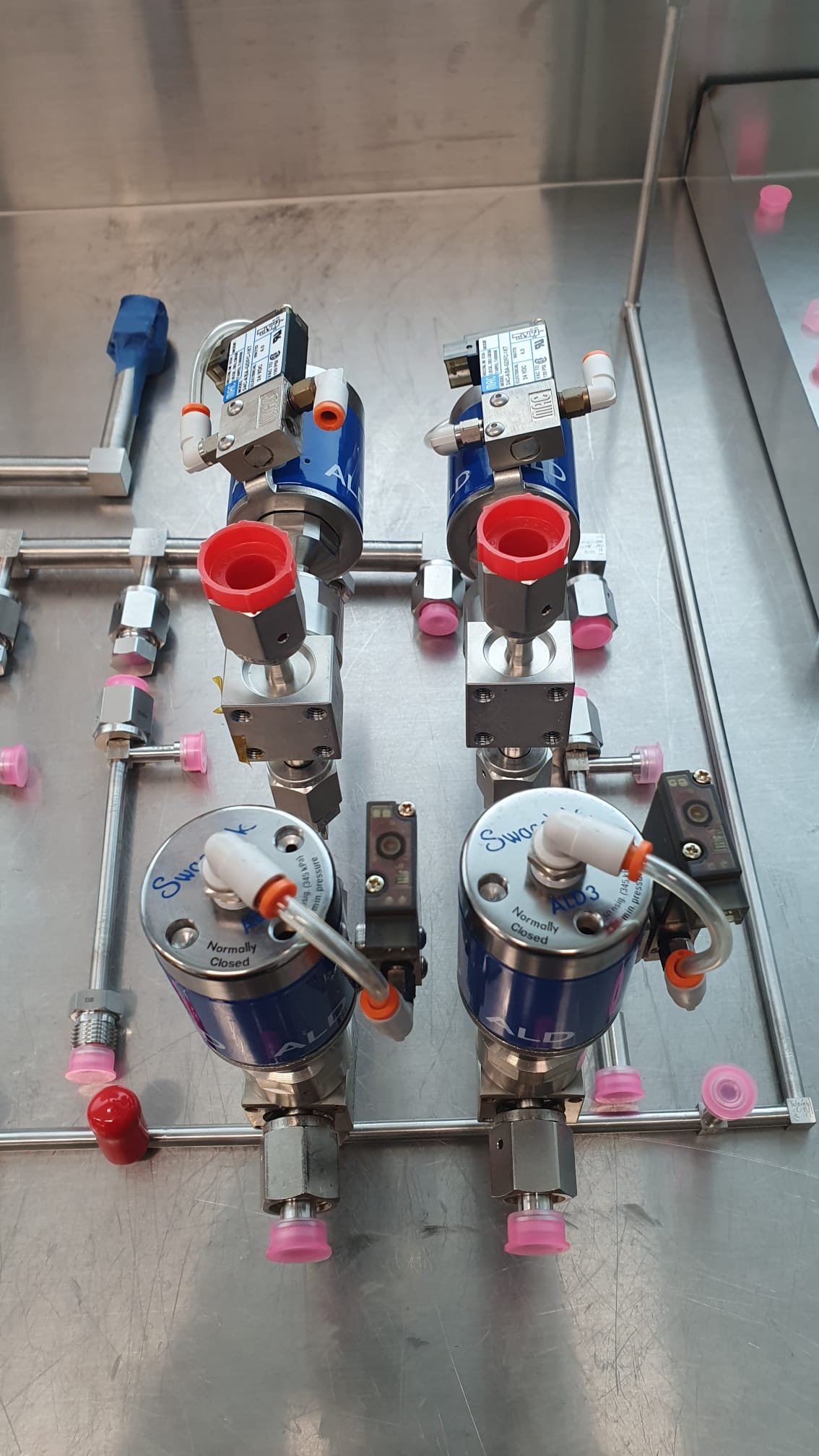

Supply and installation of UHP process gases, Helium Recovery System (Cryomech), Silane Gas Cabinet, Ammonia Gas Cabinet, Hydrogen Gas, Cabinet, TEOS Liquid Delivery Cabinet, 5 Valve Manifolds- Auto changeover Ar, 02, UHP (6N) N2, 5 Valve Manifolds- N20, C3F8, Life Safety System, CS Clean Drv Abatement System, UHP Water, Vacuum Exhaust, Process Cooling Water, Tool Exhaust, Trade waste.

• House Gas distribution for Nitrogen and Compressed Air

• Cleanroom fit out works and laboratory fit out

• UHP Gas manifold panels and Gas Cabinets

• Specialty Gas Delivery systems for individual labs from bottle sources

• Toxic, Flammable and UHP Semiconductor Gas Delivery systems with 99.999% purity, fully Orbitally welded.

• Helium Recovery system

• Life Safety system for Toxic and Flammable Gas Detection Systems.

• Oxygen Depletion Systems

• Installation of Helium compressors

• Cooling water services

• Local vacuum systems

Energy Australia Tallawarra A Power Station

Hydrogen Delivery System for Turbine Cooling

Completed Sept 2022

Umech installed over 300m of Hydrogen pipeline on site at the Tallawarra A power station and including the design and construction of a distribution shed and bulk handling area for bulk delivery and storage of Hydrogen manifold packs. Works included the hazardous area classification, design and installation with a custom nitrogen purging system and Hydrogen vent stack.

UNSW - CQC2T - INTREC

QUANTUM COMPUTING CQC2T

Completed June 2017

Design and construction of utilities and services including the installation of scanning tunneling microscopes and dilution refrigerators. Auto changeover manifolds for He, O2, Life Safety System, Process Cooling Water distribution skid and piping. Helium recovery plant.

House gas distribution for Nitrogen

Helium recover piping and custom manifold panels

Specialty gas delivery systems for individual labs from bottle sources

Ultra high purity Nitrogen, Oxygen and Argon gas manifolds and distribution piping with 99.999% purity, orbitally welded

Process cooling water system with heat exchanger and 2000lt tank

3 off chillers in duty standby configuration

Critical system uptime functionality to run 24/7/365

SIL rated Life safety system for Oxygen depletion detection

UNSW - Multiplex

MATERIAL SCIENCE ENGINEERING BUILDING

Completed June 2015

Umech installed speciality gas piping for 26 different gases over 6 floors of highly spec’d research laboratories. These included bulk gases, toxic gases, flammable gases and ultra high purity gases. The installation included all works from fitting of gas Cabinets and cylinder manifold panels in place to the hook up of tools user outlet valves in laboratories.

Additionally, Umech installed a SIL rated life safety system that manages the delivery of toxic and hazardous gas. Including oxygen depletion, exhaust pressure monitoring and toxic gas sensors.

House gas distribution for Nitrogen and Argon

Specialty gas delivery systems

Compressed air plant and distribution

Laboratory air distribution

Toxic and flammable gas detection systems

Oxygen depletion systems

Laser safety interlocks

SIL rated life safety system

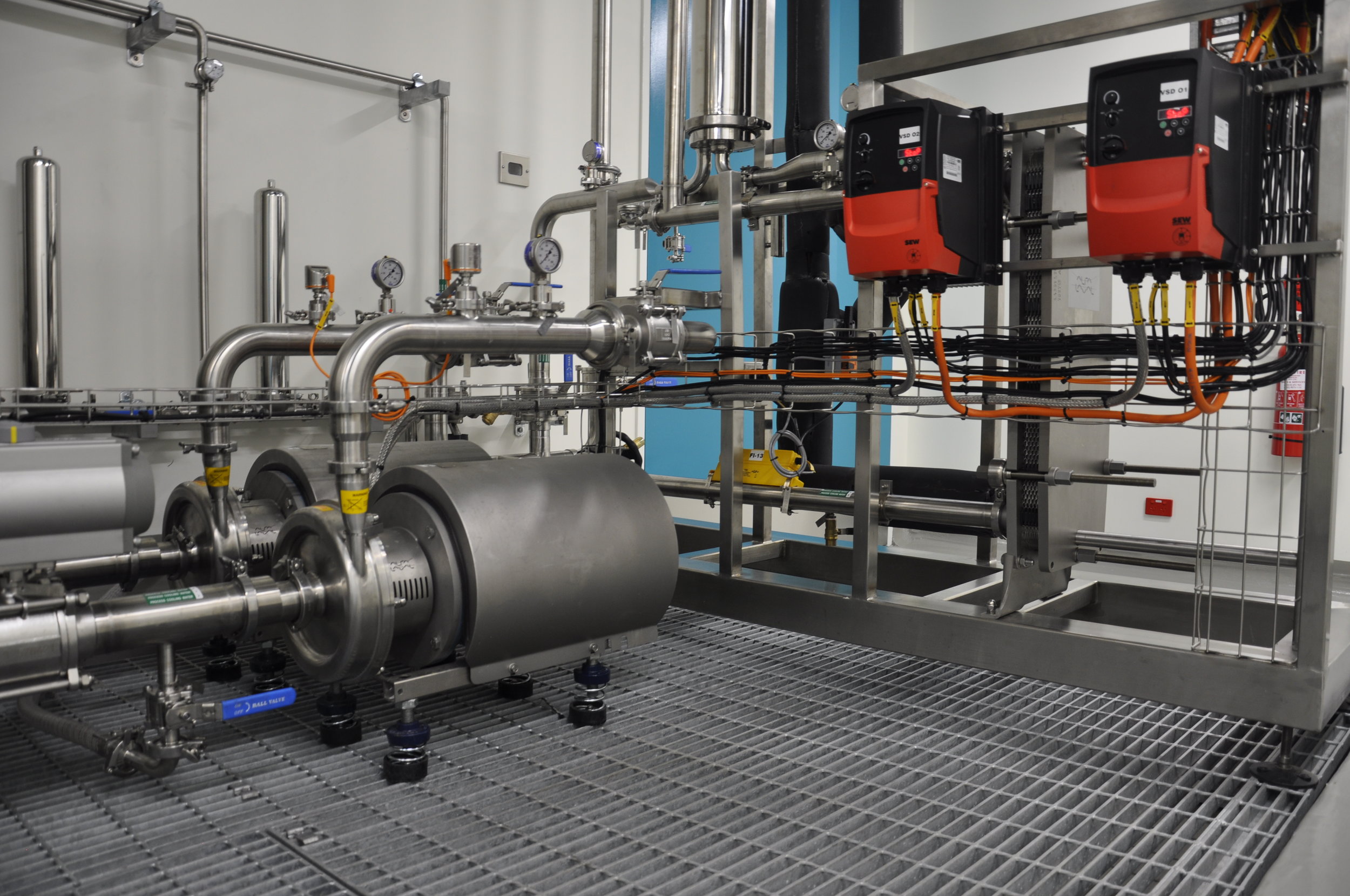

Bayer Pharmaceuticals – New Zealand

Purified Water and Water for Injection

Generation and Distribution System

Completed September 2016

Design and construction of a new Purified Water (PFW) and Water for Injection (WFI) generation and distribution plant for Bayer facility in Manukau; New Zealand. Design and construction of a clean steam generation and distribution system.

Hydraulic sizing calculations of the purified water and water for injection distribution loops

Process modelling to determine the appropriate storage tanks and generation systems capacities

System integration including importing of major equipment including water purification equipment, WFI Still, Clean Steam generator and storage vessels

3D design of prefabricated skids

Piping routing drawings

Design of the SCADA / PLC based control system, Including development of Software and Hardware Design Specifications, Electrical Drawings

Construction and Factory Acceptance Testing of the main control panel in our workshop.

Construction of process skids in our Sydney fabrication facility

Onsite installation of both the mechanical piping and electrical and controls elements of the system.

Commissioning and Site Acceptance Testing of the plants

Ongoing maintenance of the facility

Operation and maintenance manual for the plant